Agile Manufacturing in Bespoke Aerospace Components

Precision-driven manufacturing meets rapid customization in the aerospace industry's newest frontier. Agile manufacturing techniques are revolutionizing how bespoke aerospace components are produced, challenging traditional production paradigms and opening new possibilities for innovation and efficiency in one of the world's most demanding sectors.

As global competition intensified and technological advancements accelerated, aerospace manufacturers faced increasing pressure to reduce lead times, lower costs, and enhance product customization. This shift in market demands set the stage for a fundamental reimagining of aerospace manufacturing processes.

The Rise of Agile Manufacturing in Aerospace

Agile manufacturing, a concept born in the software development world, has found a new home in aerospace component production. This approach emphasizes flexibility, rapid prototyping, and iterative development to quickly respond to changing customer requirements and market conditions. In the context of aerospace, agile manufacturing allows for the production of highly customized components without sacrificing efficiency or quality.

The adoption of agile principles in aerospace manufacturing has been facilitated by advancements in several key technologies:

-

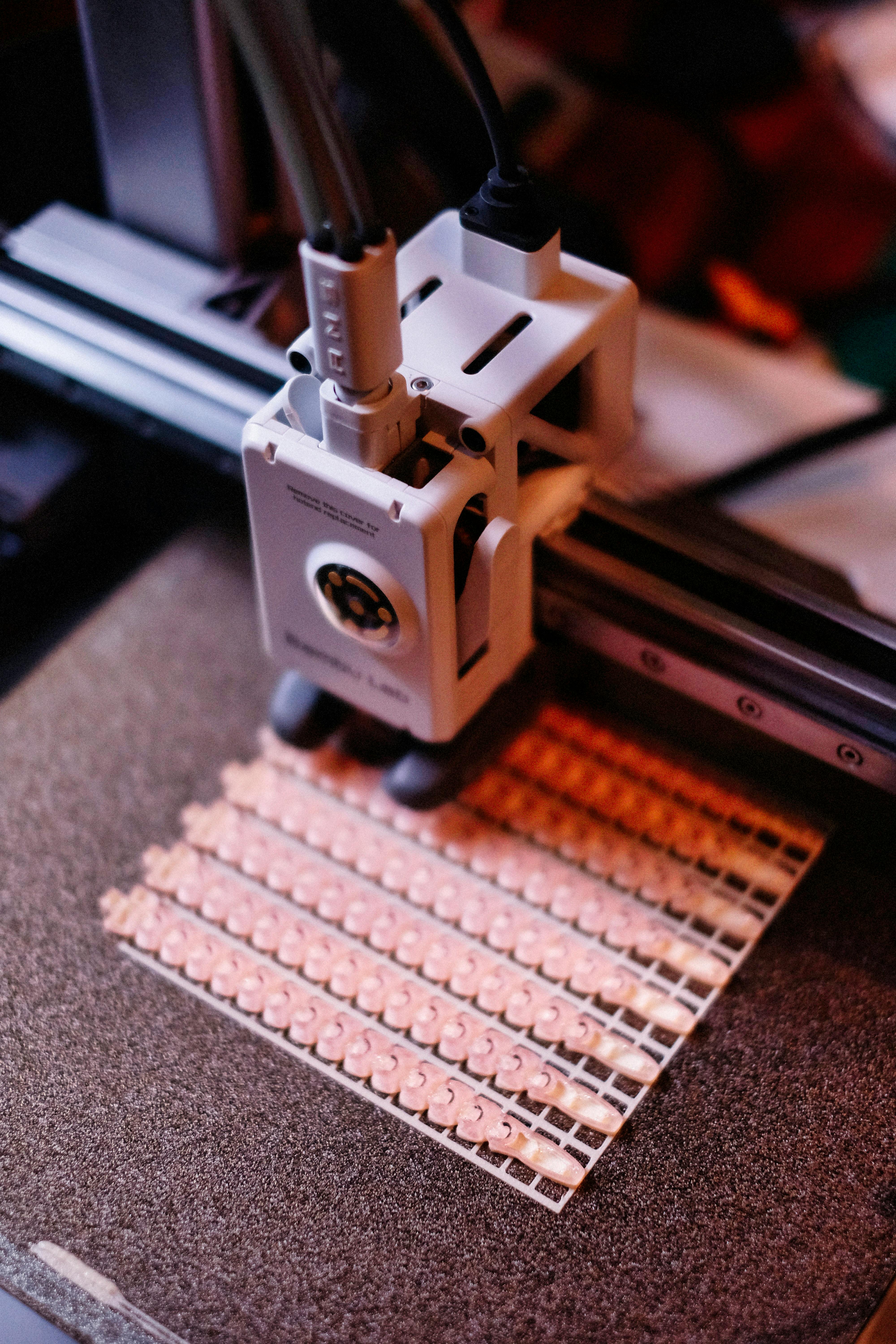

Additive Manufacturing (3D Printing): Allowing for rapid prototyping and production of complex geometries.

-

Advanced Robotics: Enabling flexible automation and quick reconfiguration of production lines.

-

Digital Twin Technology: Providing real-time simulation and optimization of manufacturing processes.

-

AI and Machine Learning: Enhancing predictive maintenance and quality control.

These technologies, combined with agile methodologies, have created a new paradigm for bespoke aerospace component production.

Implementing Agile Manufacturing for Bespoke Components

The implementation of agile manufacturing in aerospace requires a fundamental shift in both organizational culture and production processes. Key strategies include:

-

Modular Production Lines: Designing flexible workstations that can be quickly reconfigured for different component types.

-

Rapid Prototyping Cycles: Utilizing 3D printing and simulation technologies to accelerate the design-to-production process.

-

Cross-functional Teams: Bringing together design, engineering, and production experts to collaborate throughout the manufacturing process.

-

Continuous Improvement: Implementing feedback loops and data analytics to constantly refine and optimize production methods.

These strategies enable aerospace manufacturers to respond swiftly to customer demands while maintaining the high standards of quality and precision required in the industry.

Benefits and Challenges of Agile Aerospace Manufacturing

The adoption of agile manufacturing in aerospace component production offers several significant benefits:

-

Reduced Lead Times: Faster design iterations and production setup times.

-

Enhanced Customization: Ability to produce small batches of highly specialized components.

-

Improved Resource Efficiency: Optimized use of materials and energy through precise manufacturing techniques.

-

Increased Innovation: Rapid prototyping allows for more experimentation and breakthrough designs.

However, the transition to agile manufacturing is not without challenges:

-

Regulatory Compliance: Ensuring that new manufacturing processes meet stringent aerospace safety standards.

-

Skill Gap: Training workforce in new technologies and agile methodologies.

-

Initial Investment: High upfront costs for implementing advanced manufacturing technologies.

-

Supply Chain Integration: Aligning suppliers with the new agile production model.

Addressing these challenges requires a comprehensive strategy that involves collaboration between industry stakeholders, regulatory bodies, and educational institutions.

Case Study: Agile Manufacturing in Action

A leading aerospace component manufacturer recently implemented agile manufacturing principles in their production of custom turbine blades. By integrating 3D printing technology with a modular production line, they were able to reduce lead times by 40% and increase their capacity for customization by 300%. This agile approach allowed them to secure a major contract for specialized components that their competitors could not fulfill due to inflexibility in their manufacturing processes.

Future Trends in Agile Aerospace Manufacturing

As agile manufacturing continues to evolve in the aerospace sector, several trends are emerging:

-

Increased Use of AI for Design Optimization: Machine learning algorithms will play a greater role in component design, predicting performance and optimizing for manufacturability.

-

Integration of Augmented Reality in Production: AR technologies will enhance worker productivity and reduce errors in complex assembly processes.

-

Blockchain for Supply Chain Transparency: Improving traceability and quality assurance in the component supply chain.

-

Sustainable Manufacturing Practices: Incorporating eco-friendly materials and energy-efficient processes in line with global sustainability goals.

These trends point towards a future where aerospace manufacturing becomes increasingly responsive, efficient, and environmentally conscious.

Navigating the Agile Aerospace Landscape

• Invest in cross-training programs to develop a multi-skilled workforce capable of adapting to various production scenarios.

• Implement a phased approach to agile manufacturing adoption, starting with pilot projects to demonstrate value and gain organizational buy-in.

• Develop strong partnerships with technology providers and research institutions to stay at the forefront of manufacturing innovations.

• Create a culture of continuous improvement by encouraging employee feedback and ideas for process optimization.

• Establish clear metrics for measuring the success of agile manufacturing initiatives, including lead time reduction, customization capabilities, and resource efficiency.

The integration of agile manufacturing principles in bespoke aerospace component production represents a significant leap forward for the industry. By embracing flexibility, rapid iteration, and advanced technologies, aerospace manufacturers are positioning themselves to meet the evolving demands of a dynamic market. As this approach continues to mature, it promises to unlock new levels of innovation, efficiency, and customization in aerospace manufacturing, propelling the industry into a new era of agility and responsiveness.